ARCHITECTURAL PROJECTS

INDUSTRIAL

16 June, 2012

Conceptual design of a innovative industrial building for satellite manufacturing in Saudi Arabia

A contemporary production area, besides being a place of placing last generation construction machines, is essentially a space of life, of a highly skilled workforce that uses these machines.

Besides being a construction area in the strict sense, it is essentially a space of a high-level creative work (digital machines of high technology), and therefore, it has to be habitable, especially under desert conditions - these conditions are naturally hostile towards human beings, due to the extreme temperature changes. This is why such a high technology structure must be protected from its surrounding "hostile" environment, being at the same time open to an especially "constructed" ,interior, with the qualities of an "atrium-oasis", which is capable of providing comfort, filtered natural light, plantations and water elements.

It s a space that typologically refers to the structure of a residence with an enclosed yard, which is a classic, archetypical typology we encounter at the meditarrenean and Arabic civilizations.

The proposal tries to handle the main industrial volume, in a clear way, by integrating/eliminating it inside the surrounding sandy environment. Then, selected and intense parts of the whole are brought out and over the ground ,with an exaggeration in shape and height. As a result, they receive use values - shelter, shades- or symbolism and indication values - administration building, entrances, final product exit.

The ultimate goal is to give a sculptural quality, compatible with the site's character, to a purely "utilitarian" building-machine.

This gesture restores a balance between the technology futurism and the humane side of daily life. Lastly, on a purely "communicative" level, it enhances the positive surprise of the visitor, as he/she comes from outside- a silent, external space integrated in the natural environment- to a technologically sophisticated interior, with a symbolic and actual axis or center, the fertile image and reality of an oasis.

The final look of the building must convey the most sophisticated construction technology, through the use of cnc technology as well as contemporary synthetic materials, state-of-the art products of science and research.

The study is about an installation that is developed in an area of 130.000 sq.m.

Content

1. Assumptions

2. Preliminary study

3. Building structure

4. E&M

5. Bioclimatic design

6. Materials and construction methods

7. 3d Models

8.General Plans

1.Assumptions

a. An environment that encourages inspiration and creativity

b. Functional zones of the facility

c. Necessary air conditions and bioclimatic approach

d. Size of proposed building

e. Location on site

a. An environment that encourages inspiration and creativity

Inventive people are inspired by the sanctity and splendor of nature, the conversation between the past ,the present and the future of human civilization.

Inspiration and creativity is maximized in a high quality work environment , that ensures positivity ,comfort and well-being, where patrimony and state of the art technology are merged.

This merging is accomplished with contemporary translation of traditional cooling techniques of the Near East and oases-patios ,as archetypes ,that contribute to the positive energy of the industrial space .

b. Functional zones of the facility

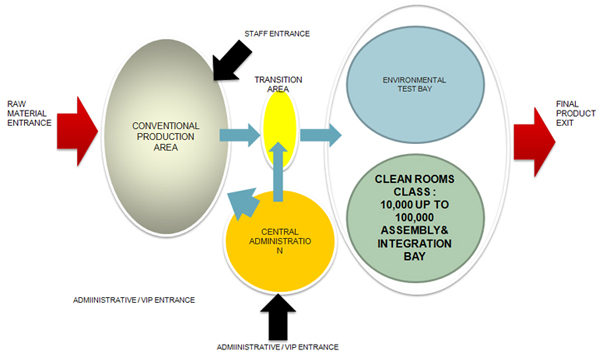

This factory is a modern post-industrial production unit. The plant consists of three basic closed types of spaces : a conventional production area, a transition area, a special production area (strictly controlled air of scalable purity, test areas, final assembly and integration, packing and delivery ) and a central administration area (management , research and development , reception and communication).

c. Necessary air conditions and bioclimatic approach

In an external environment with temperatures ranging from 8 to 47 degrees Celsius, the needs for high standards of airconditioning and bioclimatic factors are crucial. CAD-CAM procedures of high accuracy at all stages must be applied and the overall design must ensure minimum functional cost in critical and intensive air-conditioning conditions, in compliance with the L.E.E.D. certification system.

The intermediation of the atria in the overall functional structure, comes to fulfill this approach, completed with the use of shades and elements of water, which take advantage of the wind directions during the critically hot periods of the year.

d. Size of the proposed industrial facility

International practice and experience from similar facilities indicate a size ranging from 10000 to 100000 sq.m. of closed production areas, and it depends on the size of the satellites to be produced. The proposed facility consists of 25000 sq.m of closed and 26000 sq.m of semi-open spaces, and the exact decision of its size requires a more detailed report of the facility's needs.

e. Proposed location on site

The site is a few kilometers outside the city center of Riyadh, on an almost flat tableland of 1000 acres. In this area there are already some facilities of relevance, which are placed on an absolute axis of North-South.

The criteria used for placing the building onto the site ,are the optimal utilization of climatic conditions in the area with soft N, NW and NE winds , the maximum flatness of the site-a factor which favors scalability - and the minimum annoyance of existing buildings and uses.

2. Preliminary study

a. Functional structure of the facility

b. The shell typology

a. Functional structure of the facility

The individual functions are established in the building with the conscious choice of sovereign compositional elements: a central North-South axis and a secondary East-West axis, which is the axis of the building's potential scalability. These two axes form a cross, where all functions of the building, the stop and the circulation areas revolve around them, with the rational intermediation of the atria This entire layout increases the status, the stability and rationality of the whole composition. It is the main rule that constitutes it and allows the subsequent integration of morphological exceptions/deviations, which further enhance, rather than disturb, the equilibrium of the whole .

b. The shell typology

The shell typology of the complex follows certain rules, that distinguish but at the same time unite the several parts that constitute it. The conventional production area houses the conventional production process with an archetypical form, a "cave"-like structure that becomes one with the natural landscape of the sand.

The environmental test areas, the clean rooms and the assembly accommodate the perfectly technologically sophisticated and state of the art production process , with a form borrowed from the mature industrial period , from that which was back then, about 100 years ago, the latest technology, from that which was the first great enterprise of man to explore the sky .Namely, the image of a Zepellin fuselage. With this partial image of a Zepelin fuselage, covered with titanium foils- a typical space material - we express today's human ambition, trying maybe to imply its limits , its splendor and at the same time, its corruptibility.

The north-south axis, the link (the backbone) of the building is signaled by the flow of a "ribbon" that unfolds, housing the major circulations.

The office building has a distinct character, with the heliport on the roof signaling the "head" of the whole enterprise, the transparent glass outer casing of the offices which is the coexistence of two curved shapes , an ellipse and a circle (inner atrium) with a golden ratio relationship in their development , four enormous horizontal shaders, which protrude at least ten meters, protecting the glass casing from the sun, and the trollis of the shaders ,that have received a shrub planting. The need for technological and environmental efficiency are embedded in the counterpoint of the roughness of the technological construction that converses with the natural elements.

3. Building structure

Prefabricated composite construction

The building structure is composed by prefabricated elements . The ground and structure interaction requires a geotechnical study that will provide correct data for the structural design and project budget optimization. High strength structural steel S355JR is considered to be the appropriate material for the environment use. For flooring areas the composite solution will be applied, which requires steel deck and high strength concrete C 30/37.Spaceframes are considered appropriate for column-free areas and cellular beams for E&M installations. The B.I.M. application for advanced and accurate fabrication allows for all prefabricated elements to be transported by containers from any available fabrication plant and to be easily installed on site.

4. E&M

The electric and mechanical installations (plumbing installations, fire protection systems, cranes, heating ,ventilating & air conditioning (HVAC Systems),electrical systems) on the site must be in conformance with local and international standards and regulations, "clean spaces" requirements and the manufacturing procedure. The design must be easy to construct ,economical and adaptable and the structures must be common for all system networks

5. Bioclimatic design

The application of bioclimatic technology reassures the appropriate audiovisual thermal behavior of the building, while minimizing the energy consumption for heating and cooling by 70% .This is achieved by placing shades for the glass building, e-low windows , natural ventilation, plantation, geothermal power system through air and water, solar panels, water cascades and an appropriate choice of materials.

6. Construction methods and materials

The materials and construction methods have different qualities, depending on the nature of each space. The roofs for the conventional industrial spaces are made of aluminium matchboard suspended ceiling in white colour, with vinyl topping for the high purity spaces, and drywall constructions with integrated conceiled lighting for the office spaces.

The internal partitions for the conventional industrial spaces are made of prefabricated aluminium partitions with double soundproofing glazing or soundproofing vinyl panels, in thickness depending on the particular requirements of each space, with certified partitions depending on the purity grades for the high purity spaces, and with soundproofing glazing with internal blinds and drywall partitions for the office spaces.

The floors for the conventional industrial spaces are made of special resin self-leveling flooring, and with wooden pre polished flooring for the office spaces.

The outer casing was treated differently, in order to achieve the desirable insulation and thermal conditions and provide bioclimatic qualities. The external roofs for the conventional industrial spaces have three layers that consist of especially prefabricated sand plates (final external layer), prefabricated soundproofing aluminium panels and lastly, air vacuum .The roofs at the high purity spaces are made from a layer of Titanium or titanium zinc sheet coating (external layer), a layer of prefabricated soundproofing aluminium panels and air vacuum. At the office zone, the building is topped with a green roof.

The handling of the outer shell is completed with the outer casing, which is made from prefabricated soundproofing aluminium panels at the industrial spaces and aluminium curtain walls with double e-low glazing and integrated remote controlled blinds at the patios and office areas.

7. 3d models

Conventional production area- raw material entrance.

Test bay area- clean rooms- final assembly- product exit.

Aerial view.

Entrance for employees.

Northeastern general view.

Northeastern view of the office building.

Southern view of the office building.

Visitors' and office building entrance.

Visitors floor and heliport, View of the atrium from the visitors entrance.

8. General plans

Level-3,70 , entrances, handling, auxiliary spaces, parking lot, geothermal installations. Level 0,00 production areas, research and development area.

This preliminary study was assigned to us in October 2011. It was delivered by the end of November 2011 in Dubai.

The study was designed by the following groups:

Architectural design : Andreas Kyranis architects

Team: Andreas Kyranis, Kyriaki Stefanidou, Marilena Tsouka, Dimitris Soulinas,Markos Mazarakis, Nikos Mpaskozos, Thomas Vournazos

Structural design: SDENG steel detail engineering, Aristodimos Theodorou

Bioclimatic design: Niki Founta

Mechanical design: RODAKAS, Antonis Froudakis, Christos Moisidis

Texts, theoretical documentation : Andreas Kyranis

Translation: Marilena Tsouka